Link, Knuckle Press

KDHK Series 250/300/400/500/600/800

▪ Precision increased and problems with C-Type frame solved

▪ Useful for Press work due to use of knuckle joints

▪ Guarantee slide path and maintain precision via plunger guide

▪ Suited for transfer, progressive work because of its wide slide and bolster plate

▪ This 8 phases structure guide type is unaffected by eccentric axial loading and shows exceptional precision

▪ Guarantees reliability and high torque via wet multi type clutch / brake

▪ Protects the mold and press by using Hydraulic overload protector system

▪ Improves equipment by adding a touch screen on the pendant shaped control which shows mechanical info, abnormalities, etc.

▪ Apt for high quality product production

▪ Reduces impact and extends mold life

▸ Slide adjustment system

▸ Photoelectric safety device

▸ Recirculating auto oil lublication system

▸ Air ejector

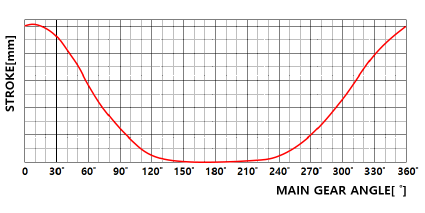

Slide Motion-curve

Standard Specifications

| 사양(Specification) | Unit | KDHK-250 | KDHK-300 | KDHK-400 | KDHK-500 | KDHK-600 | KDHK-800 |

|---|---|---|---|---|---|---|---|

| Capacity | ton | 250 | 300 | 400 | 500 | 600 | 800 |

| Limit of Capacity | mm | 7 | 7 | 7 | 7 | 7 | 7 |

| Stroke | mm | 200 | 250 | 250 | 300 | 300 | 350 |

| Number of Stroke | spm | 40 | 40 | 40 | 35 | 35 | 30 |

| Die height | mm | 550 | 600 | 600 | 650 | 700 | 800 |

| Adjustment of Slide | mm | 120 | 150 | 150 | 150 | 150 | 150 |

| Area of Slide | mm | 2,600 × 800 | 2,700 × 900 | 2,800 × 1,100 | 3,000 × 1,200 | 3,000 × 1,200 | 3,200 × 1,300 |

| Area of Bolster | mm | 2,600 × 900 | 2,700 × 1,000 | 2,800 × 1,200 | 3,000 × 1,300 | 3,000 × 1,300 | 3,200 × 1,400 |

| Working height | mm | 1,000 | 1,100 | 1,200 | 1,300 | 1,400 | 1,500 |

| Main Motor | kw × p | 22 × 4 | 30 × 4 | 37 × 4 | 45 × 4 | 55 × 4 | 75 × 4 |

| Adjusting Motor | kw × p | 2.2 × 4 | 3.7 × 4 | 3.7 × 4 | 5.5 × 4 | 5.5 × 4 | 5.5 × 6 |

| Die Cushion(Option) | |||||||

|---|---|---|---|---|---|---|---|

| Capacity | ton | 12.5 × 2 | 12.5 × 2 | 15 × 2 | 15 × 2 | 15 × 2 | 15 × 2 |

| Stroke | mm | 130 | 130 | 150 | 150 | 150 | 150 |

| Pad Area | mm | 1,750 × 550 | 1,750 × 550 | 1,900 × 720 | 1,900 × 720 | 1,900 × 720 | 1,900 × 720 |

| Air Pressure | kg/cm² | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

Features

- ▪ Stirdy enough for long-term operation

- ▪ Efficiency increased due to an addition of knuckle joints and customized BDC(Bottom Dead Center)

- ▪ Efficiency increased for operations such as Coining, Embossing, etc.

Option Item

- ▪ A.C Inverter / V.S Motor

- ▪ Die cushion

- ▪ Anti-vibration unit

- ▪ Quick Die Change System

- ▪ Knock out device

- ▪ Auto transfer device

- ▪ Short Stroke High Speed

- ▪ Long Stroke